SUSTAINABILITY

UPCYCLING

THE LIFE OF The Barrel

The Lyons family, proud owners and operators of Lexington Brewing & Distilling Co., carries a legacy spanning seven generations of brewers, coopers, and distillers. Today, we continue that tradition by crafting innovative products that celebrate their distinct points of origin, while remaining mindful of our responsibility to leave a better future for the next generation.

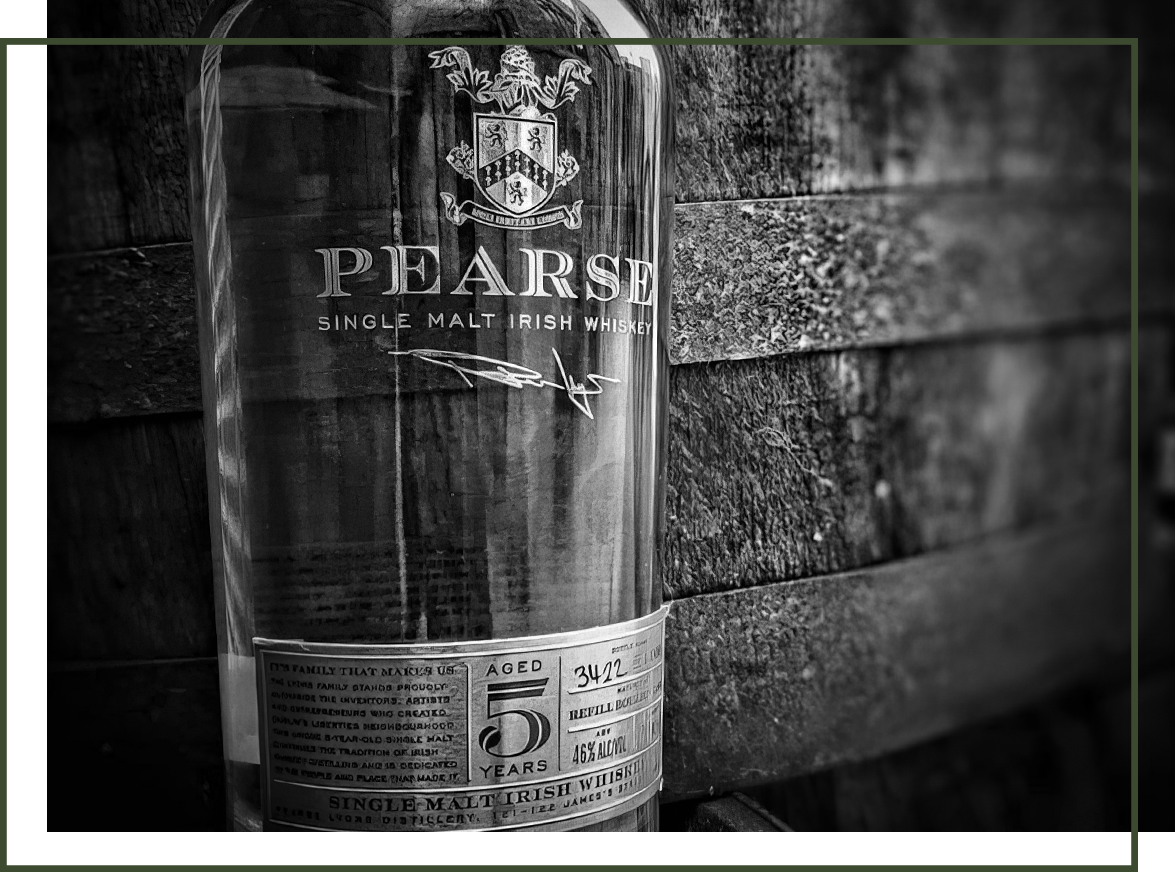

One of our cornerstone sustainability initiatives is our Life of the Barrel production philosophy. Every Town Branch Bourbon barrel is thoughtfully upcycled to create additional products that share our DNA—from Town Branch Bourbon to Kentucky Bourbon Barrel Ale, followed by Town Branch 7-Year Kentucky Single Malt Whiskey, before ultimately traveling to Pearse Lyons Distillery in Dublin, Ireland, where the barrels continue their journey aging Irish whiskey. This approach ensures high-quality production oversight at every stage, while honoring the long life of each oak tree used to craft our barrels—cherishing and celebrating the wood’s contribution far beyond a single use.

Every whiskey barrel begins long before distillation—with an oak tree rooted deep in the forest. American white oak, the wood required for aging Kentucky bourbon, grows slowly. From seedling to harvest, an oak tree typically takes 70 to 100 years to mature enough to be turned into barrels. During that time, it absorbs minerals, develops tight grain structure, and builds the natural compounds that will one day shape a whiskey’s flavor.

A single mature oak tree produces surprisingly few barrels. On average, one oak yields only two to three full-sized 53-gallon barrels. Much of the tree is lost during milling, drying, and coopering to ensure only the tightest, most suitable staves are used—essential for holding liquid and aging whiskey safely. That means every barrel represents decades of natural growth and an extremely limited resource.

By law, Kentucky Straight Bourbon must be aged in new, charred oak barrels. The intense charring unlocks powerful flavors—vanilla, caramel, spice, and oak—but it also means the barrel can only be used once for bourbon. After a single aging cycle, the barrel is no longer eligible to hold bourbon again. This legal requirement makes bourbon uniquely dependent on a continuous supply of new oak, placing enormous importance on how barrels are treated after their first use.

While a barrel may be “used up” for bourbon, it still has years of life left to give. Reusing barrels for other spirits, beer, wine, or finishing whiskey allows distillers to extend the useful life of a resource that took nearly a century to grow, reduce demand for newly harvested oak, create layered, nuanced flavors that evolve with each use, honor the craftsmanship and natural materials behind every barrel. At Town Branch, we choose to do this internally where barrels often live multiple lives—from bourbon to beer, to finishing whiskey, and beyond. Each use extracts something different from the oak, creating depth while respecting the tree’s long journey from forest to glass.

Using barrels more than once isn’t just about flavor—it’s about stewardship. When a tree spends a lifetime growing, the least we can do is ensure its contribution to whiskey lasts far longer than a single use. Every reused barrel tells a longer story, of patience, craftsmanship, and respect for the land.

While a barrel may be “used up” for bourbon, it still has years of life left to give. Reusing barrels for other spirits, beer, wine, or finishing whiskey allows distillers to extend the useful life of a resource that took nearly a century to grow, reduce demand for newly harvested oak, create layered, nuanced flavors that evolve with each use, honor the craftsmanship and natural materials behind every barrel. At Town Branch, we choose to do this internally where barrels often live multiple lives—from bourbon to beer, to finishing whiskey, and beyond. Each use extracts something different from the oak, creating depth while respecting the tree’s long journey from forest to glass.

Using barrels more than once isn’t just about flavor—it’s about stewardship. When a tree spends a lifetime growing, the least we can do is ensure its contribution to whiskey lasts far longer than a single use. Every reused barrel tells a longer story—of patience, craftsmanship, and respect for the land.

The Bourbon

Behind The Beer

Our brewery and distillery form a marriage of skills that drives the one-of-a-kind flavor in our beers and whiskies. Our award-winning Town Branch® Bourbon made with a higher-malt mash. It is aged in new, charred white oak barrels for a golden amber color and incredibly rich, complex flavors that make our bourbon timeless.

Crafting the beer of

Bourbon Country

After the newly brewed Kentucky Bourbon Barrel Ale® goes onto bottling, the barrels continue their life with a third filling to create our Town Branch® Kentucky Single Malt Whiskey aged for a minimum of seven years. Within Town Branch Distillery rests the oldest Kentucky single malt stocks in the world.

The oldest Kentucky

single malt stocks

And while the beer goes onto bottling, the barrels continue their life with a third filling to create our Town Branch® Kentucky Single Malt Whiskey aged for a minimum of seven years. Within Town Branch Distillery rests the oldest Kentucky single malt stocks in the world.

OUR STORY CONTINUES. FOLLOW US!

@LEXINGTONBREWINGCO @TOWNBRANCHBOURBON